How to safely store multiple Fire Extinguishers.

Organized Blue Steel Fire Extinguisher Rack

What is a Fire Extinguisher Storage and management process?

Over the last 30 years, I visited hundreds of our clients’ facilities, workshops, railyards, and job sites. The progress in making our industrial work environments safer has been significant. So here at Blue SteelCo, we are proud to assist our customers and help make their workspaces safe, more organized, and efficient.

We developed our fire extinguisher rack for a specific reason: It helps reduce trip hazards caused by emptied or outdated bottles lying around the property.

OSHA continues to to cite, Fall Protection Citations and Slip/Fall injuries are at the top of the list. The discharged extinguishers could be mistaken for a charged unit should a fire erupt, resulting in injuries to your workers.

We spoke to plant managers, safety supervisors, maintenance managers, and others, we developed our plan for the perfect fire extinguisher rack.

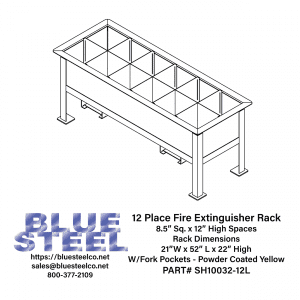

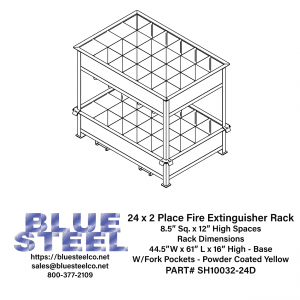

- The Fire Extinguisher Rack must hold multiple bottles; this makes the accumulation of expired, discharged, and empty fire extinguishers organized and effective.

- Forklift access makes transporting empty extinguishers to a refill location, and full extinguishers for distribution in large yards or facilities a snap.

- Heavy Duty fabrication and durability, we fabricated our first units almost 20 years ago, and are still in use. Our Industry Standard steel fabrication and zinc-rich primed and powder-coated finish provides a product suitable for any commercial or industrial facility.

Pricing for all sizes and configurations Click Here

Key Benefits of Our Fire Extinguisher Storage Rack

Eliminate trip hazards

Correctly identify discharged and charged fire extinguishers

Speed up your recharging service

Checking and keeping fully charged fire extinguishers is a crucial factor in fire safety. Our handy Fire Extinguisher Storage Rack is part of your solution.

Forklift pockets make it easy to move and 24 Spots 8-1/2″ Square Will hold most standard-size bottles. The overall size is 52″ long x 35″ deep and 16″ high.

Pallet Jack movable Bulk Fire Extinguisher storage options are also available.

All steel construction and powder-coated safety yellow.

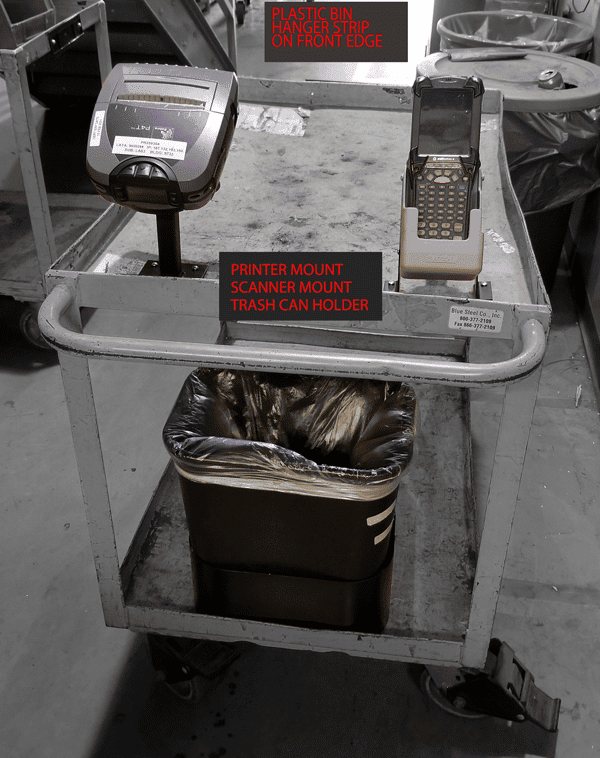

Hand Truck build for moving fire extinguishers

Fire Safety on the Move

Keep your fire extinguishers close at hand with our 2 Place Fire Extinguisher Hand Truck. This sturdy hand truck is built to transport two fire extinguishers, making them easily accessible even in tight spaces. With a 54″ handle, you can maneuver it effortlessly through busy rail yards or over uneven terrain, ensuring that safety equipment is always within reach.

Features:

- Holds 2 fire extinguishers

- 54″ handle for easy maneuverability

- 10″ Diameter x 2.5″ Wide wheels

- Durable construction for long-lasting use

Whether you’re working in a rail yard, an industrial environment, or any other location where fire safety is paramount, our Fire Extinguisher Hand Truck is the ideal solution.

#firesafety #safetyfirst #industrial #fireextinguisher #handtruck #railroad #manufacturing

BUY NOW

Organized Blue Steel Fire Extinguisher Rack. Keep your workplace safe organized and clean. When there is a designated process for the storage of tools and supplies, you move closer to your 5S goal. Sort, Set in order, Shine/Sweep, Standardize, and Sustain.